Analysis of Immersion Cooling-Based Thermal Management Solutions for Pure Electric Vehicle Battery Packs

Abstract

This paper takes the thermal management system of power battery packs for pure electric vehicles as the research object. Through comparison with the traditional battery pack heat exchange plate technology, a brand-new immersion thermal management system for battery packs is designed. The system uses high-efficiency insulating fluorinated liquid as the heat exchange medium, completely immersing battery cells in the fluorinated liquid, and realizes heat exchange with each cell in the battery pack by regulating the temperature of the fluorinated liquid. The new system fundamentally solves the problem of uneven temperature among cells inside the battery pack, enabling the realization of high-voltage and high-power super fast charging, and directly improving the service life of the battery pack and the driving range of the vehicle. Finally, the performance differences between the immersion system and the traditional battery pack heat exchange plate are compared through system bench tests to verify the efficiency of the new system.

Introduction

The battery pack of a pure electric vehicle must operate at an ideal temperature to ensure its service life and charging/discharging efficiency, thereby guaranteeing the vehicle’s driving range. At present, almost all vehicle manufacturers implement temperature control of the battery pack through cold plate heat exchange. In other words, antifreeze with different temperatures is provided by Chiller or PTC components and flows into the heat exchange plate of the battery pack, realizing temperature control and regulation of the battery pack through heat exchange between the heat exchange plate and the cells inside the battery pack.

Based on the battery thermal management system, this paper designs a “full-clad” temperature control system for battery cells to achieve an optimal battery thermal management solution, providing a better thermal management system for electric vehicle super fast charging and battery life improvement. The design of the immersion heat exchange flow channel inside the battery pack is the focus of this analysis.

2 Heat Exchange Plate System

2.1 Introduction to Heat Exchange Plate System

In the heat exchange plate-based battery thermal management system, the heat exchange plate, as an important component of the battery pack, typically conducts heat with the cells inside the battery pack to achieve the heating and cooling functions of the battery pack. Figure 1 shows a schematic diagram of the heat exchange plate-based battery thermal management architecture.

Through analysis of the structural characteristics of the heat exchange plate itself, it can be found that any design must include inlets and outlets for the heat exchange medium. The heat exchange medium flows inside the heat exchange plate and contacts the battery cells for heat exchange, resulting in obvious high and low temperature zones on the surface of the entire heat exchange plate, which clearly demonstrates the problem of uneven temperature. The positional relationship between the heat exchange plate and the battery cells, as well as the internal flow channel structure, are shown in Figure 2 and Figure 3.

2.2 Temperature Distribution Analysis of Heat Exchange Plate

The simulation analysis of the surface temperature uniformity of the heat exchange plate yields more explicit results. The test conditions mainly include four aspects: inlet flow rate of 1.66 L/min, inlet temperature of 15°C, outlet temperature of 17.96°C, and outlet pressure drop of 37 Pa.

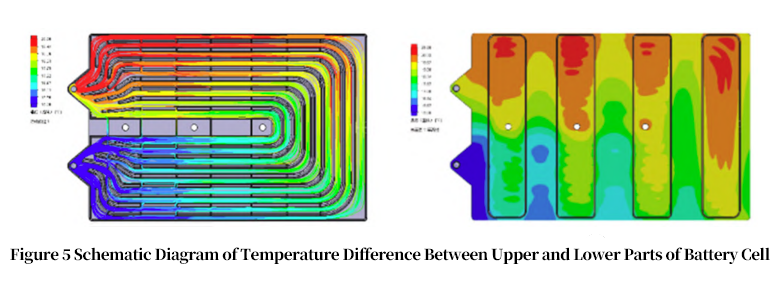

Figures 4 and 5 show the temperature field analysis of the cold plate and the temperature difference diagram between the upper and lower parts of the cell, respectively. According to the simulation results, the maximum temperature difference on the surface of the heat exchange plate is basically 5–6°C. Although this can meet the service requirement that the maximum temperature difference between cells in the battery pack does not exceed 8°C, it is still not an ideal design. Meanwhile, it is difficult to meet the requirements of future high-power super fast charging, and the cells will directly affect the service life of the battery pack.

In addition, the cells in the battery pack have a three-dimensional structure with multiple surfaces. The conductive heat exchange of the heat exchange plate usually only contacts one surface of the battery cell, fundamentally failing to achieve a full – scale and three – dimensional heat exchange effect with the battery cell. This is also the biggest drawback of such designs.

3 Immersion-Type Battery Thermal Management System

3.1 Introduction to Immersion Thermal Management System

Aiming at the problems of the heat exchange plate system, designing a thermal management system with “full-clad” battery cells has become particularly important and urgent. Against this backdrop, the immersion-type battery pack thermal management system emerged. The immersion-type battery pack thermal management system completely immerses battery cells in high-pressure resistant and insulating liquid, enabling the entire battery cells to fully exchange heat with the liquid, thus achieving temperature regulation of the battery pack.

The high-voltage insulating heat exchange medium used in this paper is fluorinated liquid, which has excellent thermal stability, chemical stability, and moderate solubility. It has an ozone depletion potential (ODP) of 0 and a significantly reduced global warming potential (GWP), alleviating the environmental burden. The parameters of the fluorinated liquid are shown in Table 1.

3.2 Structure and Principle of Immersion Thermal Management System

By using fluorinated liquid instead of antifreeze and removing the heat exchange plates in the battery pack, the battery cells are completely immersed in the fluorinated liquid. The Chiller cools the fluorinated liquid to reduce the temperature of the battery cells, and then the WPTC heats the fluorinated liquid to raise the temperature of the battery cells. Figure 6 shows the thermal management architecture diagram of the fluorinated liquid.

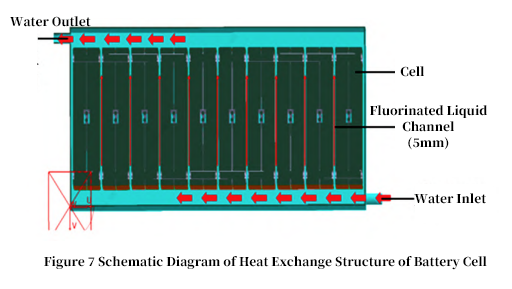

To ensure that the battery cells in the battery pack can fully exchange heat with the fluorinated liquid, an efficient heat exchange flow channel needs to be designed for the battery cells. A 5mm gap is reserved between each cell to ensure that the fluorinated liquid can pass through this gap to complete heat exchange with each battery cell. The simplified diagram of the battery cell heat exchange structure is shown in Figure 7.

3.3 Testing of Immersion-Type Battery Thermal Management System

A bench test was conducted to compare the differences between the immersion thermal management solution for battery packs and the traditional battery heat exchange plate solution. The test was carried out under the fast-charging condition of the battery pack, with the same Chiller providing the same cooling capacity for both heat exchange media and the water pumps operating at identical power. An equal number of battery cells were placed in fluorinated liquid and on heat exchange plates respectively to initiate the experimental testing.

Prior to the test, one temperature sensor was installed at the top and middle of each battery cell, totaling 20 measurement points grouped into 10 pairs. Figure 8 shows a schematic diagram of the temperature measurement point distribution on the battery cells.

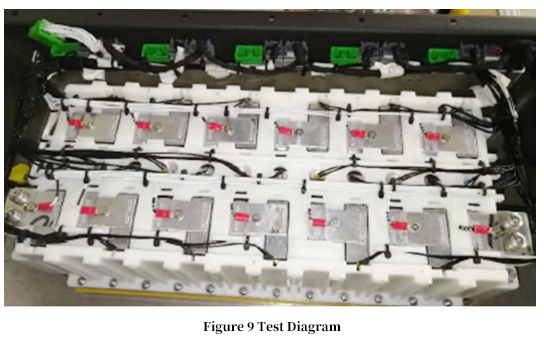

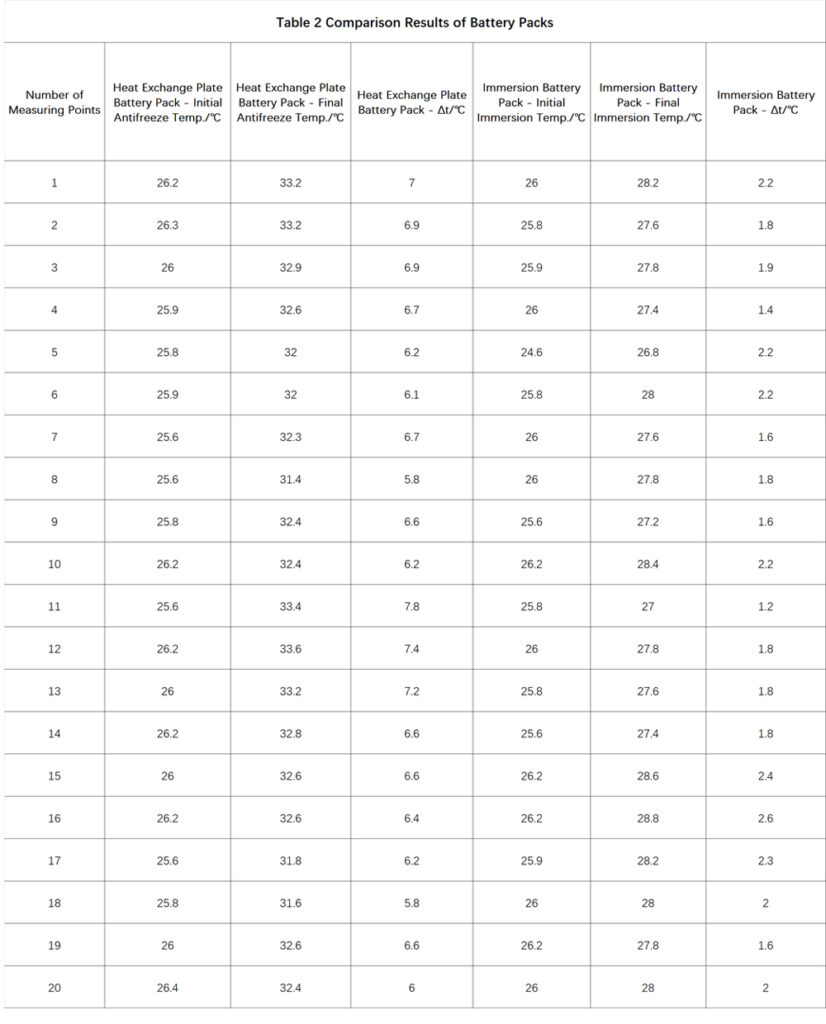

The battery cells were placed in the battery pack, and fluorinated liquid was injected to start the test. The test diagram is shown in Figure 9. The test conditions were: 2C rate charging and a heat exchange medium flow rate of 550 L/h, using fluorinated liquid and antifreeze for testing respectively. The comparison results of the battery packs are shown in Table 2.

The average value of the two temperature test points on each battery cell was taken as the temperature value of the battery cell, and the temperature curve is shown in Figure 10.

As shown in Figure 10, for the traditional thermal management of battery packs using heat exchange plates, the temperature difference between battery cells ranges from 5 to 8°C. In contrast, the immersion thermal management technology can control the temperature difference between battery cells within 2 to 3°C. This indicates that the immersion battery pack thermal management technology enables more efficient heat exchange of battery cells, improves temperature uniformity inside the battery pack, and ensures the service life of battery cells and the driving range of the vehicle.

4 Conclusions

In summary, the immersion thermal management technology has incomparable characteristics and advantages. Especially for future charging rates of 4C or even 5C, the immersion battery pack thermal management technology is bound to be more widely applied and popularized.

Active Community Global, Inc (ACG EVENTS Global) is a leader in conference planning and production. We produce world-class conferences like summits, technical forums, awards ceremony, company visiting and so on, focusing on areas of most relevance to our served industry sectors. We are dedicated to deliver high-quality, informative and value added strategic business conferences where audience members, speakers, and sponsors can transform their business, develop key industry contacts and walk away with new resources.