A Visual Guide to Core Components of New Energy Vehicle Thermal Management Air Conditioner R&D [aCrd Thermal Management]

HVAC is the abbreviation of Heating, Ventilating and Air Conditioning. It refers to the unit installed under the automobile instrument panel with heating, ventilation and air conditioning functions, which includes main components such as blower assembly, heater core, evaporator core, mixing damper and mode damper.

The HVAC assembly combines the air intake unit, blower unit, air purification unit, refrigeration unit, heating unit, etc., in accordance with certain rules. With the continuous development of the automotive industry, the design and manufacturing of HVAC assemblies need to meet the following requirements:

•Compact Packaging

•Higher Cooling and Heating Capacity

•More New Functions

•Lighter Weight

•Lower Cost

The HVAC assembly can be classified into single-zone air conditioning and multi-zone air conditioning according to its structure.Single-zone air conditioning adjusts the in-vehicle environment as a whole.Multi-zone air conditioning divides the cockpit into the driver’s area, front passenger’s area, and rear passenger’s area, enabling independent environmental air conditioning for each zone.

For the heating function, traditional vehicle heaters utilize the heat from high-temperature cooling water from the engine to exchange heat with the surrounding air, achieving in-vehicle heating. In contrast, new energy pure electric vehicles adopt electric auxiliary heaters.

Heater cores can be classified into tube-fin heaters and parallel-flow heaters according to their structures:

Tube-fin heaters are manufactured by passing multiple U-shaped circular aluminum tubes through layers of aluminum fins, followed by expanding processes and water tank assembly.

Parallel-flow heaters use multiple parallel aluminum flat tubes with louvered serpentine fins embedded between them. After water tank assembly, they undergo brazing and other processing steps.

Comparison of the two heater types: Parallel-flow heaters exhibit higher heat transfer performance. Under the same external conditions, the heating capacity of a parallel-flow heater with the same heat dissipation volume is 25%-40% higher than that of a tube-fin heater.

Air Intake and Discharge Functions

For the HVAC assembly to achieve cooling or heating, moving air must conduct heat exchange on the surface of heat exchangers. Providing this airflow requires a blower assembly and an air intake device.

•The main function of the air intake device is to introduce external air into the HVAC system. This external air is divided into air from outside the vehicle (Freshair, fresh air circulation) and air from inside the vehicle (Recirculation, recirculated air).

•The blower assembly serves as the power source for air flow, primarily composed of an impeller, DC motor, speed control resistor (or speed control module), motor support, and air guide housing. The speed control resistor or module is the key component for regulating air volume.

Air Purification Function

The in-vehicle air quality is directly related to the ventilation and purification capacity of the HVAC assembly. To achieve air purification and improve air quality, an air purification device is essential.

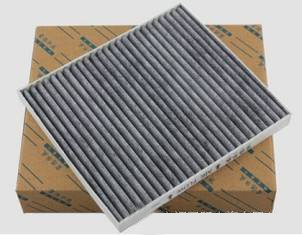

Passenger vehicles generally use air filters to purify and improve in-vehicle air. According to filter media, they can be divided into:

•Particle filters (capable of filtering dust in the air)

•Carbon fiber filters (capable of filtering odors and dust in the air)

•Negative ion filters, etc.

Currently, particle filters and carbon fiber filters are the most widely used. They are typically installed between the blower and evaporator to filter the air inside the vehicle and the air circulating between the interior and exterior. This removes dust, impurities, smoke odors, pollen, etc., from the in-vehicle air or incoming air, ensuring passengers’ physical health and eliminating interior odors.

Air Mixing and Distribution Functions

The HVAC assembly achieves air volume distribution and temperature regulation through the coordinated movement of various dampers. Temperature adjustment is primarily realized by the movement of mixing dampers, enabling functions such as face-level, foot-level, and defrost modes. All damper movements, including damper rotation and water valve opening/closing, rely on motion mechanisms. These mechanisms can be manually operated via cables or controlled by micro-motors.

Through air volume distribution, functions such as ventilation mode, foot-level mode, ventilation-foot-level combined mode, and defrost mode are integrated to create a comfortable in-vehicle environment.

With the vigorous development of the automotive industry, future consumers will place greater emphasis on vehicle safety, stability, comfort, entertainment, assistance, and energy conservation & emission reduction. New automotive air conditioning products that better meet energy-saving and environmental protection requirements will become more popular. In terms of technological development trends, automotive air conditioners will evolve towards environmentally friendly, green, compact, energy-efficient, comfortable, and automated solutions.

Active Community Global, Inc (ACG EVENTS Global) is a leader in conference planning and production. We produce world-class conferences like summits, technical forums, awards ceremony, company visiting and so on, focusing on areas of most relevance to our served industry sectors. We are dedicated to deliver high-quality, informative and value added strategic business conferences where audience members, speakers, and sponsors can transform their business, develop key industry contacts and walk away with new resources.