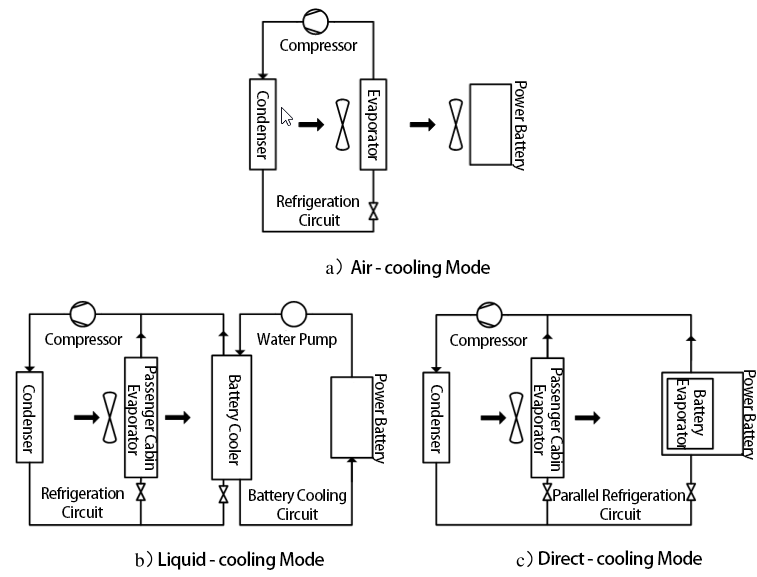

Currently, thermal management systems for power batteries can be mainly categorized into four types: natural cooling, air cooling, liquid cooling, and direct cooling. Among these, natural cooling is a passive thermal management method, while air cooling, liquid cooling, and direct cooling are active ones. The primary difference between the latter three lies in the type of heat exchange medium used. This article focuses on discussing the advantages and disadvantages of the direct cooling solution compared with the liquid cooling method, which is most widely adopted in the industry.

1. Advantages of Direct Cooling

Performance and COP

Since the direct cooling system can eliminate one heat exchange process, it reduces thermal resistance from an extra heat transfer step and lowers the heat exchange temperature difference, resulting in excellent heat transfer performance. Furthermore, the refrigerant boils and vaporizes in the battery cold plate to absorb heat, which significantly enhances the heat exchange capacity.

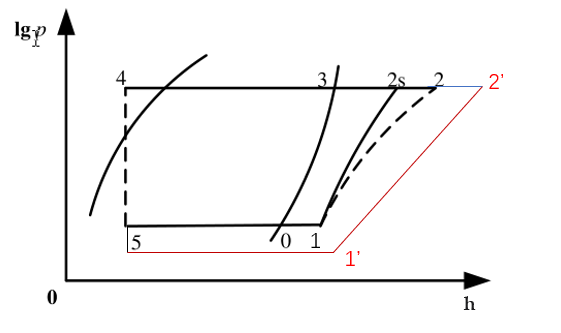

Meanwhile, the reduction in heat exchange temperature difference allows the evaporation temperature of the cold plate to increase, which in turn raises the suction pressure and reduces the pressure ratio. From the perspective of the pressure-enthalpy diagram, the COP (Coefficient of Performance) of the system changes from the original formula (h2′ – h1′) / (h1′ – h5) to (h2 – h1) / (h1 – h5). As can be intuitively seen from the diagram below, the system’s COP is improved. Readers interested in this can conduct simulations to understand the specific differences.

System Complexity

The original liquid cooling system required a chiller, which was then connected to the water-cooled plate via water pumps and pipes. With direct cooling, the entire water circulation system for the battery loop can be completely eliminated. Instead, the refrigerant component originally part of the chiller is integrated into a large plate installed in the battery. From a schematic perspective, this reduces the number of components; from a control perspective, it removes a controllable part like the water pump. In terms of layout space, it also saves the space occupied by components such as the chiller, water circuits, and water pumps.

2. Disadvantages of Direct Cooling

Pressure Resistance and Sealing Issues

The evaporation pressure of a refrigerant system can generally reach 3–4 atmospheres. To put this in perspective: the author specifically checked a Fissler pressure cooker (purchased for around RMB 2,000), which has a maximum pressure resistance of 150 kPa (equivalent to 1.5 atmospheres). Considering how thick the steel must be to prevent a pressure cooker from exploding, one can imagine the engineering challenges faced by the cold plate— the system’s high-pressure resistance and sealing requirements are far stricter than those for water circuits. In contrast, the operating pressure of a liquid-cooled plate typically does not exceed 1.3 atmospheres at most. (Admittedly, pressure and force cannot be directly compared, but this analogy makes the difference more intuitive. Once again, the author clarifies that this is by no means an endorsement for the pressure cooker.)

According to the paper Effects of Gas Medium, Pressure, and Calibration Method on the Leak Rate of Vacuum Leaks from the Institute of Atomic and Molecular Physics, Sichuan University, the leak rate is proportional to the square of the pressure and the viscosity coefficient. Additionally, based on Avogadro’s Law, it is inversely proportional to the molar mass of the substance. Therefore, the leak tightness requirement for refrigerant cold plates is hundreds of times higher than that for water-cooled plates. (Readers interested in this topic can explore how the annual refrigerant leak rate is converted to the helium leak rate, and ultimately use the helium leak test result as a benchmark to compare the two requirements.)

Temperature Uniformity

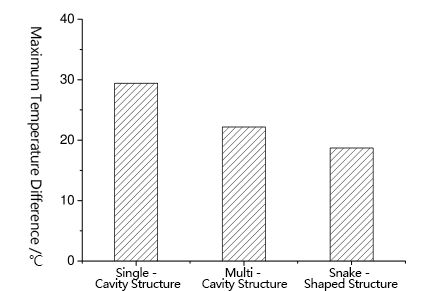

Those who have worked with evaporators know that there is usually a requirement for the temperature uniformity of the evaporator surface. This is because uneven distribution of the refrigerant can lead to significant temperature differences across the surface. Similarly, a direct cooling plate functions as an evaporator, so this issue must also be addressed.

For a battery pack, it is not only necessary to ensure that the cells operate within a reasonable temperature range but also generally required to control the temperature difference between different modules to not exceed a specific value. For example, blade batteries contain many modules, so it is essential to ensure that the temperature of the battery cold plate itself is relatively uniform, or at least controllable—and this is precisely a problem that direct cooling plates need to solve.

From the paper Thermal Management Performance Analysis of Direct-Cooled Power Batteries by Bao Wendi from Jilin University, it was found that the maximum temperature difference of a direct cooling plate can be close to 20°C, which has a significant impact on the temperature uniformity of the battery (batteries generally require a temperature difference between cells of no more than 5°C). In contrast, for a water-cooled plate, assuming a heat exchange capacity of 5 kW and a water flow rate of 20 L/min, the temperature difference between the inlet and outlet water is only a few degrees—making it much easier to meet the battery’s temperature uniformity design requirements.

Limitations in Heat Pump Mode

In the case of direct heating, the discharge pressure at the compressor outlet typically reaches over 60°C, and the condensation temperature also exceeds 40–50°C—this is higher than the optimal temperature range for batteries.

Additionally, for current R134a refrigerant systems, the maximum limit for heating is generally in scenarios where the ambient temperature is around minus ten degrees Celsius. When the temperature drops further, the heat pump can no longer operate and thus cannot heat the battery. This requires the battery to be equipped with an additional electric heater, which may eliminate the system’s cost advantage.

System Oil Return Issue

In battery direct cooling technology, the battery cold plate is connected in parallel to the refrigerant system. Moreover, the cold plate has a very large surface area and a long flow path, which gives rise to the issue of compressor lubricating oil return. Under certain conditions, refrigerant oil may accumulate inside the cold plate, leading to oil shortage and failure of the compressor.

Overall Summary

In general, since direct cooling plates involve two-phase flow, they are not advantageous compared to liquid cooling in terms of theory, control difficulty, or component costs. This explains why the liquid cooling solution remains the mainstream in the current market.

However, direct cooling still holds considerable application prospects. Especially as requirements for battery energy density and fast-charging speed continue to increase, the direct cooling solution—with its advantages in volume, weight, cooling speed, and performance—may find application in more vehicle models.