In refrigeration air conditioning and heat pump systems, refrigerants act as working fluids. An ideal refrigerant should possess stable chemical properties and inertness, along with excellent heat transfer characteristics and fluid flow properties. Additionally, it must be compatible with other substances, miscible with lubricating oils, non-toxic, low-cost, and environmentally friendly.

R134A Freon is a new type of refrigerant belonging to the hydrofluorocarbon (HFC) category. It has a boiling point of -26.5°C. Its thermophysical properties are close to those of R12, with an Ozone Depletion Potential (ODP) of 0, but a Global Warming Potential (GWP) of 1300. It does not damage the ozone layer in the atmosphere and has been promoted as an environmentally friendly refrigerant in recent years, though it contributes to the greenhouse effect. It is also the most commonly used refrigerant at present.

With the advancement of the Montreal Protocol and the Kyoto Protocol, increasing attention has been paid to replacement technologies for hydrochlorofluorocarbons (HCFCs). Therefore, how to select appropriate refrigerants and use more energy-efficient equipment has become an urgent issue.

R1234yf and R744 are two mainstream alternative refrigerants.

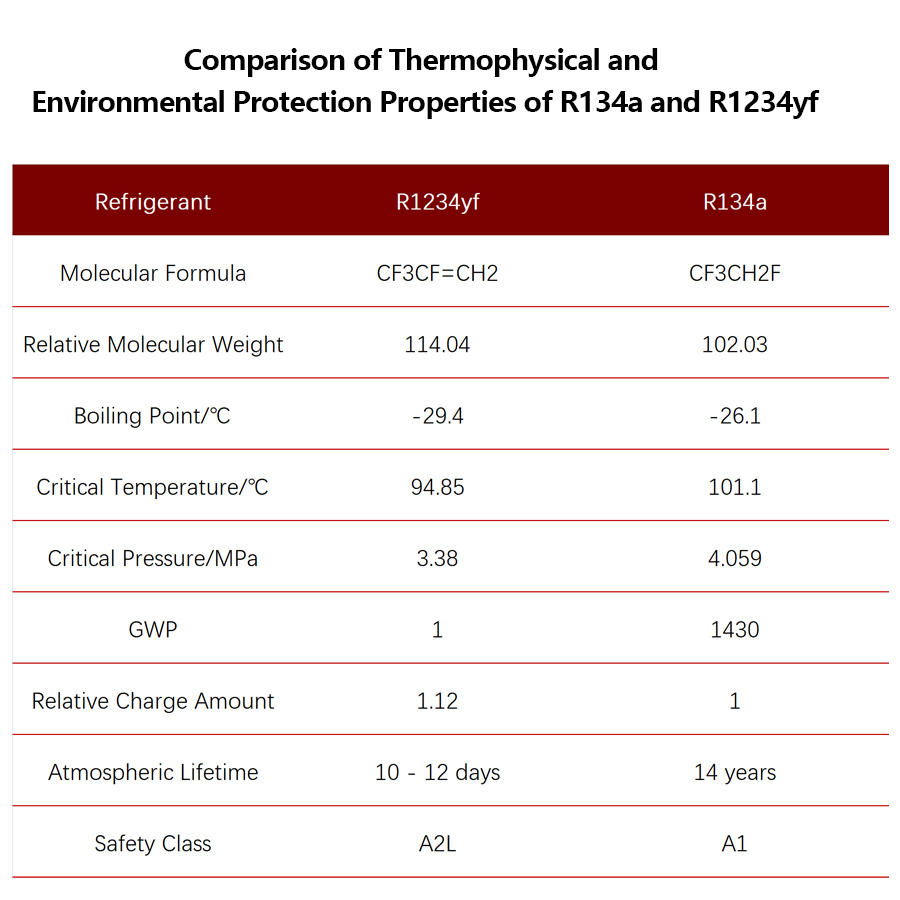

R1234yf shares many similar parameters with R134a:

1. In terms of thermophysical properties, R1234yf can be directly charged into the original air conditioning system for operation, reducing R&D and manufacturing costs;

2. In terms of heating performance, R1234yf also suffers from the problem of low operating efficiency at low temperatures, which is a drawback of R134a.

In terms of safety, R1234yf has a safety classification of A2L, meaning it is weakly flammable. Jointly developed by DuPont (USA) and Honeywell, R1234yf is subject to patent monopolies. The European Union has previously conducted an anti-monopoly investigation into this refrigerant. Additionally, R1234yf exhibits poor performance in winter: at temperatures below -5°C, its heating effect is limited.

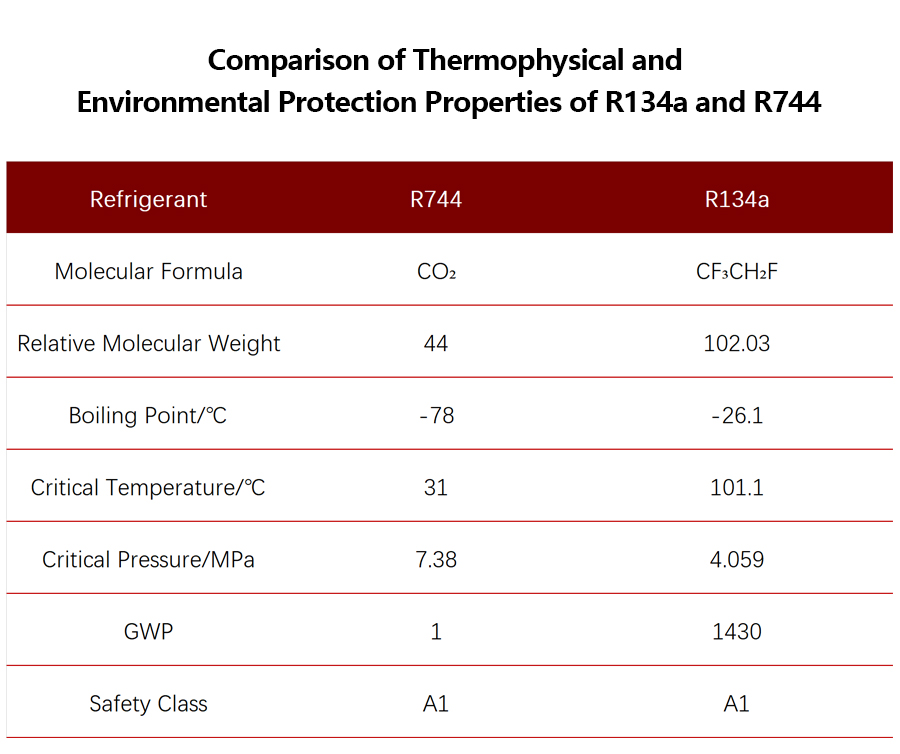

R744 Heat Pumps,Popular in Japan, R744 heat pumps are a new generation of heat pumps that use carbon dioxide (CO₂) as the working fluid. R744 (carbon dioxide) is also one of the best alternatives to R134A.

R744 has a GWP (Global Warming Potential) of 1 and a safety classification of A1, making it environmentally friendly and safe. There are significant differences between the parameters of R744 and R134a, which are specifically reflected in their application in heat pumps as follows:

1. Due to R744’s relatively low boiling point, the refrigeration system requires high pressure during operation, which increases new R&D and manufacturing costs;

2. R744 has excellent heating performance: even when operating at -20°C, its COP (Coefficient of Performance) can reach 2, which is significantly higher than that of R134a.

When selecting R744 as the refrigerant, the pipeline is required to be high-pressure resistant, which increases the cost of components such as pumps, valves, and water-cooled pipes. However, R744 performs better in low-temperature environments and can be adapted for use in winter in Northeast China. R1234yf, by contrast, behaves the opposite way. Beyond the aforementioned factors, the selection of refrigerants also involves considerations such as patented technologies and discourse power in the future of the field.

Currently, there are differences in refrigerant choices among automakers. German automakers, represented by Volkswagen and Mercedes-Benz, mainly opt for R744, while American automakers, represented by General Motors and Ford, primarily choose R1234yf.